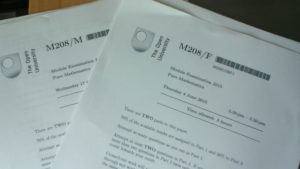

Last week I took the exam for the level 2 Open University module M208 (Pure Mathematics). Just like last year with MS221, I’d not studied as much as I wanted, and had given myself two clear days before the exam to “cram” as much as possible and hope for the best. I want to make it very clear that this is a really poor strategy for any student wanting to revise and please with you not to copy this method! Continue reading M208 – revising in 2 days