At the end of my last post in this series, we had added the cables and feeder components. This post focuses on the print head assembly, covering issues 68 – 71 of 3D Create and Print by Eaglemoss Technology. If you’ve skipped a part of this series you can start from the beginning, including details of the Vector 3 printer I’m building on my 3D printer page.

-

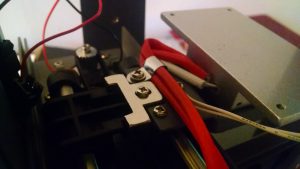

Print head heater block connected to the motor Print head heater block: Issue 68 comes with the a pre-assembled heater block, supply pipe and print nozzle, as well as the calibration gauge and nuts and screws. The first step is to get the nut onto the edge of the heater block assembly. I found that the first few turns were very difficult. I was probably a little too hesitant as I didn’t want to cross thread the nut, but after 10 mins of trying I just went for it using the larger spanner to give extra force – once I had it past the first three turns it moved quite freely and I got it to the end of the thread about 4mm from the block. The grub screws are pretty easy to fit, but remember not to over-tighten. Finally, thread the print head assembly into the print head holder – make sure that the thread only just reaches the feeder bearing and then undo by a quarter. I found that this left the larger hole in the heater block furthest away from the motor. Tighten the nut up to the holder and keep the calibration safe for later1.

-

Cooling fan attached to print head Print head cooling fan: issue 69 provides the fan for the print head and heat sink. Align the heat sink over the print head assembly, with the fan on top. The diagrams indicated that the wires should be on the heat sink side, so that’s how I put it in. Use the two long bolts to connect the fan and heatsink to the print head assembly.

-

Connector board and holder attached Print head connector board: Issue 70 provides a connector board and holder that attaches to the assembly. Align the holder with the assembly on the sprint side. Attach with the bolts – make sure you use the bolts and not the collar-headed screws. Attach the connector board, ensuring the LED is on the nozzle side and use the self tapping screws to attach the board. Connect the cooling fan to socket J3 and the feeder motor into J4. Note the position of the cooling switch, which should be towards the LED to ensure the fan is controlled by the software rather than being on continuously.

-

Old heater removed ready for the new part. Replacement build plate heater: Issue 70 also comes with a B pack. Eaglemoss have found that under testing the build plate heater did not have a long enough lifespan, so they have provided replacement parts. Since these parts come with issue 70, I’m including them here, even though this involves extensive surgery of the main printer assembly. While on the surface this is an undoing of about 6 issues’ worth of build, the rest of the printer is now in the way, making it harder to undo the screws and access the parts. Make sure you have some little dishes or bags to hold the screws as you remove them and label them so you have the right parts to hand when it comes to rebuilding. Unclip the heat retardant cover and unscrew the bolts from the build plate base. Then release the y-axis cover – note that there are three of one bolt and one of the other so keep them separated and labelled. Unscrew the two screws from the top of the y-axis cover to release the heater cables holder (that was the cause of so much pain!).

New heater in place with the metal clamp Unscrew the bolt from the plastic cable clamp and put to one side. Remove the plastic cable clamp – this is no longer required. carefully snip off the two cable ties at either end of the cable holder. Remove the wire protection coil and the wire strengthener and discard. Disconnect the heater wires from ribbon cable, which should be just below the y-axis assembly and unthread the heater wires from the cable holder. At this stage, you should be able to remove the heater itself from the build plate, however, I found that I needed to unscrew the heater plate holder and loosen the tensioning bolts below in order to remove it and get the new one in. The new heater has larger strong plastic sheathing and the heater element is rated “16” rather than “15-5”, although voltage and Wattage remain the same.

Feed the wires back through the holder and add the cable ties Insert the new heater and retighten the tensioning bolts if you need to. Attach the build plate to the y-axis although note the new placing of the screws and that the replacement metal clamp is on the opposite side. Catch all four cables in the metal clamp and fix using the washer headed bolt, ensuring a very tight u-turn in the wires. Enjoy threading the wires through the holder again, although a lot easier this time 😉

Everything back together

The old plastic parts, no longer needed… Ensure the stiffening shield is outside of the holder. add the cable ties and snip off the excess. Thread the motor wires through the cable holder at the end and add the larger cable tie, removing the excess. Now comes the fiddly bit. With the main frame in the way, attach the cable holder to the underside of the y-axis cover using the two self-tapping screws. Give yourself plenty of room for this, and somewhere you can easily find the screws if you drop them. Once you’ve managed to get the two screws in, slide the y-axis cover back over the rest of the assembly, making sure no wires are trapped, and add the bolts, ensuing that the longer bolt is in the corner with the z-shaft support.

Finally, reattach the build plate with the final four bolts and clip back the heat retardant cover. It should be like nothing has changed other than some spare plastic and the old heater of course.

-

Heat sensor attached to the print head and connector board Print head heat sensor: Issue 71 comes with the heat sensor and is nice and easy to finish off this set of issues. Loosen the grub screws with the allen key and slide the heat sensor into the print head heater block. Tighten the screws ensuring the sensor is flush with the edge of the heater block. Plug the wires into socket J1 on the connector board.

So, the print head is really getting there now and we’ve done our first bit of maintenance on the existing machine, which has been a really good exercise in the future for diagnosing issues and replacing parts going forwards.

- I do wonder why these components we need to save aren’t just issued at the point we need them? ↩